Extrusion Dies & Components

Customization

Co-Development

Production

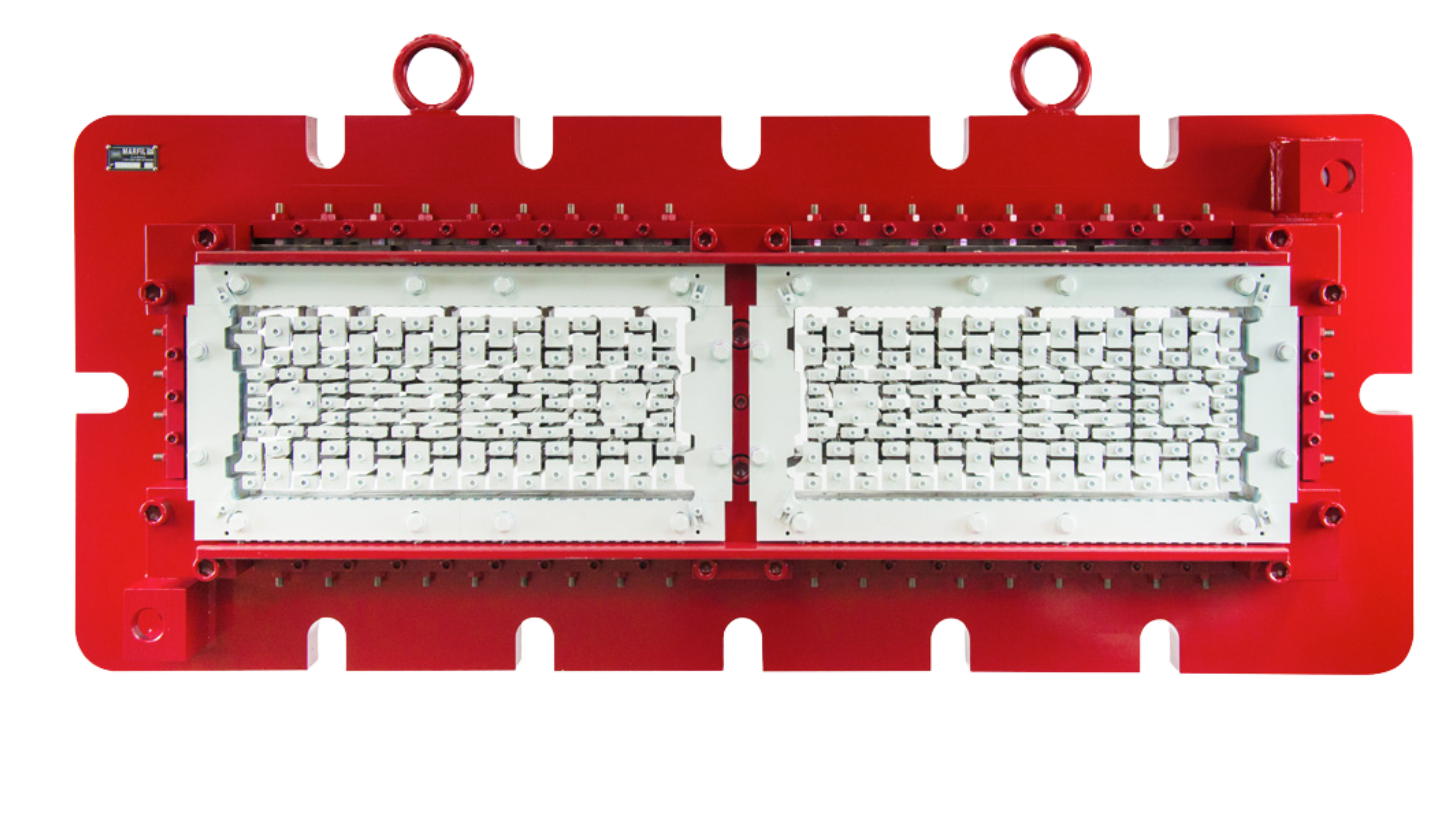

Extrusion Dies High Performance

BMI extrusion dies are co-developed to ensure precise and durable extrusion, tailored to the specific requirements of your clay products.

With advanced design tools, we optimize performance using wear-resistant materials, ensuring long-lasting durability.

Each die undergoes rigorous quality control to guarantee maximum reliability and high-quality production, even in demanding industrial environments.

Benefits BMI Extrusion Dies

Custom-designed extrusion dies, engineered for lasting performance.

Expertise & Know-How

Proven expertise in wear-resistant materials and extrusion technologies.

Engineering & Co-Development

Close collaboration with our clients to design tailor-made solutions adapted to their needs.

Spare Parts Availability

A responsive stock to ensure the continuity of your production.

Technical Support & Assistance

End-to-end support, from design to equipment commissioning.

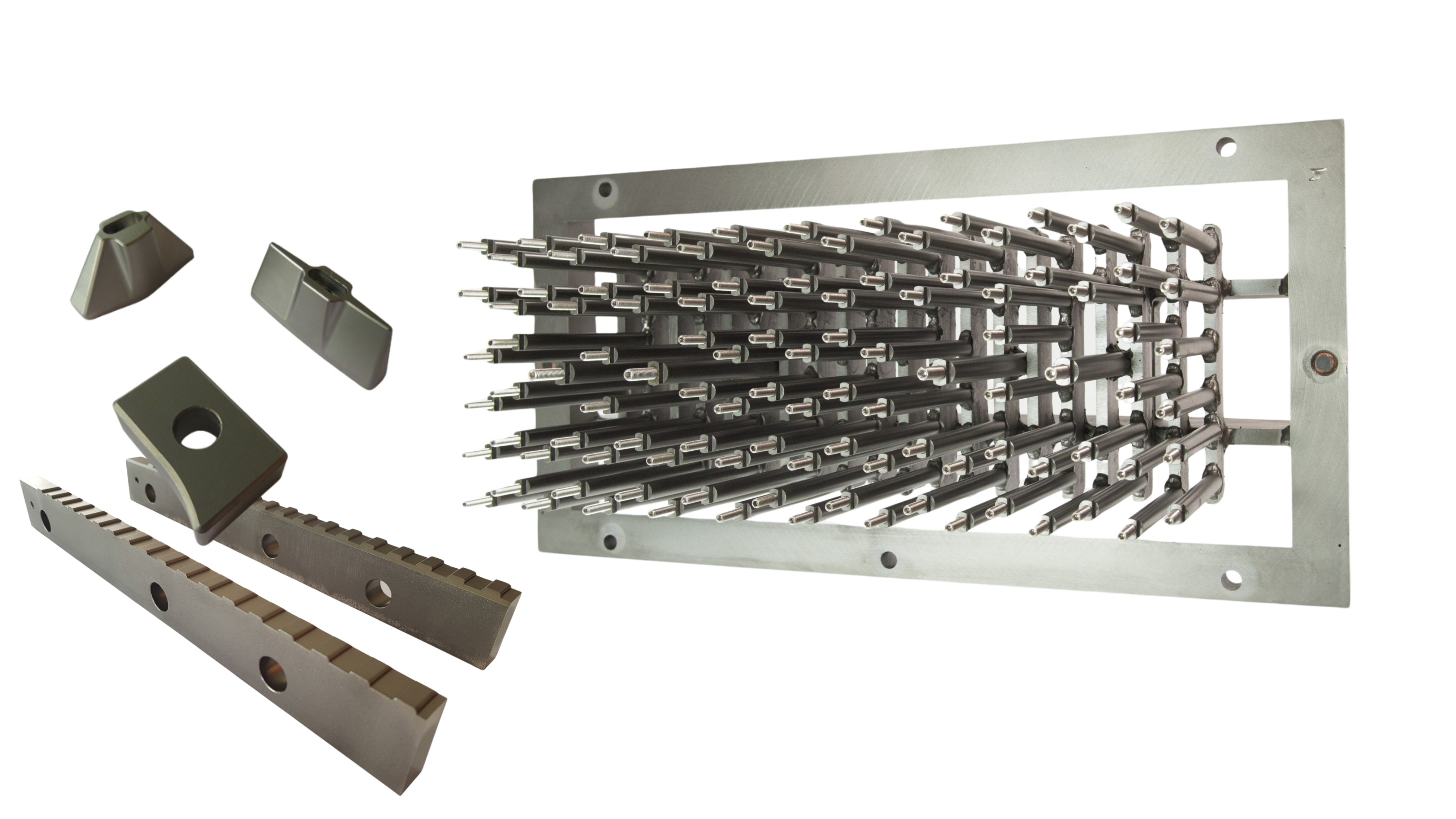

High-Performance Wear-Resistant Materials

Material selection based on client-specific constraints and objectives.

100% Integrated Industrial Tool

Comprehensive management of design, manufacturing, and optimization to ensure consistent quality.

Simplified Commissioning

Ready-to-use solutions, tested and optimized for seamless integration.

Ease and efficiency for your maintenance operations.

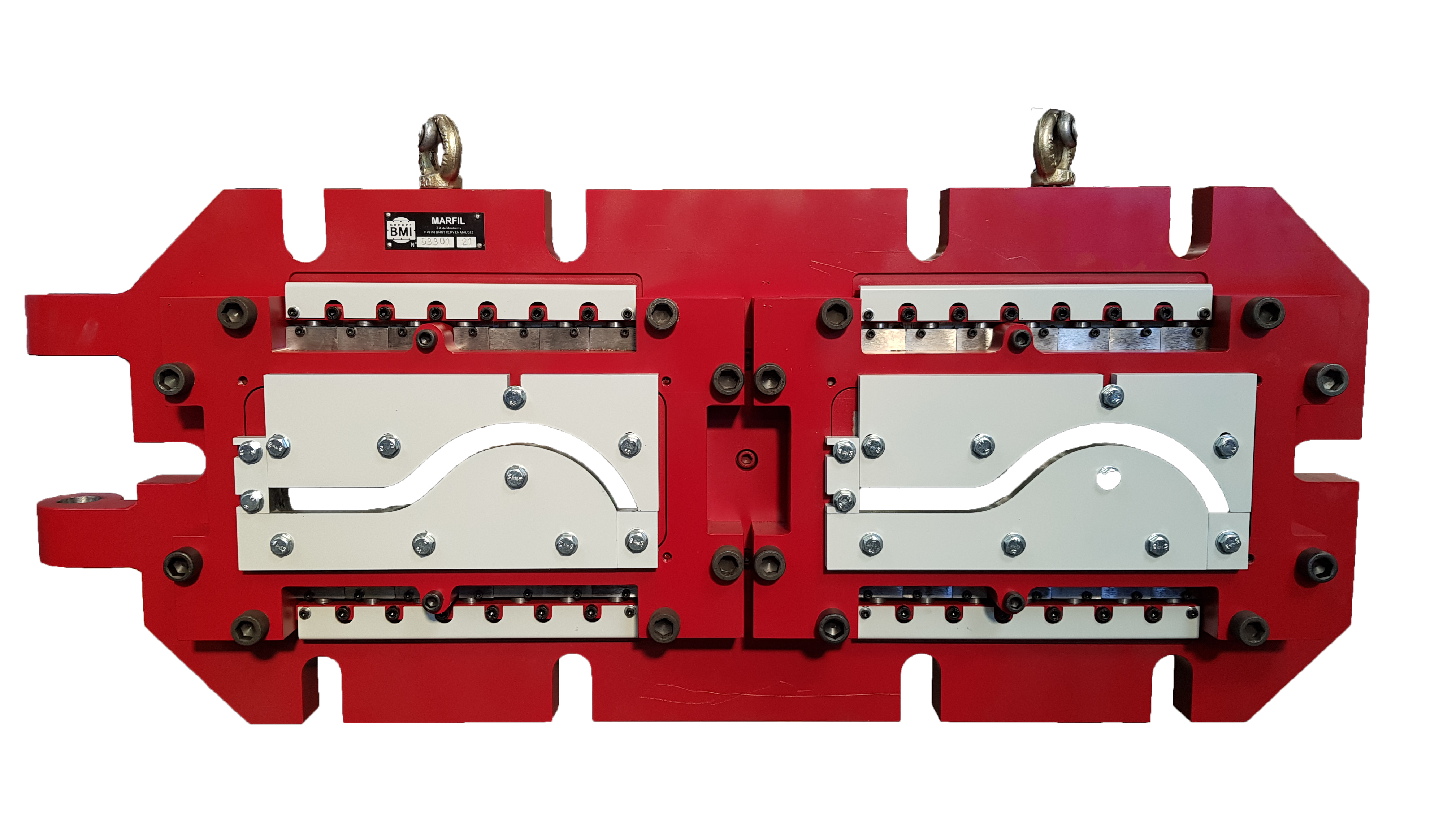

Die Handling System

BMI develops an innovative range of die handling systems designed to simplify the maintenance of your equipment.

With our assembly table, spare part replacements are quick and efficient, reducing downtime and improving productivity.

Our custom-designed systems ensure safe and easy handling, tailored to the needs of your production line.