Solutions for every need

Extrusion dies for bricks

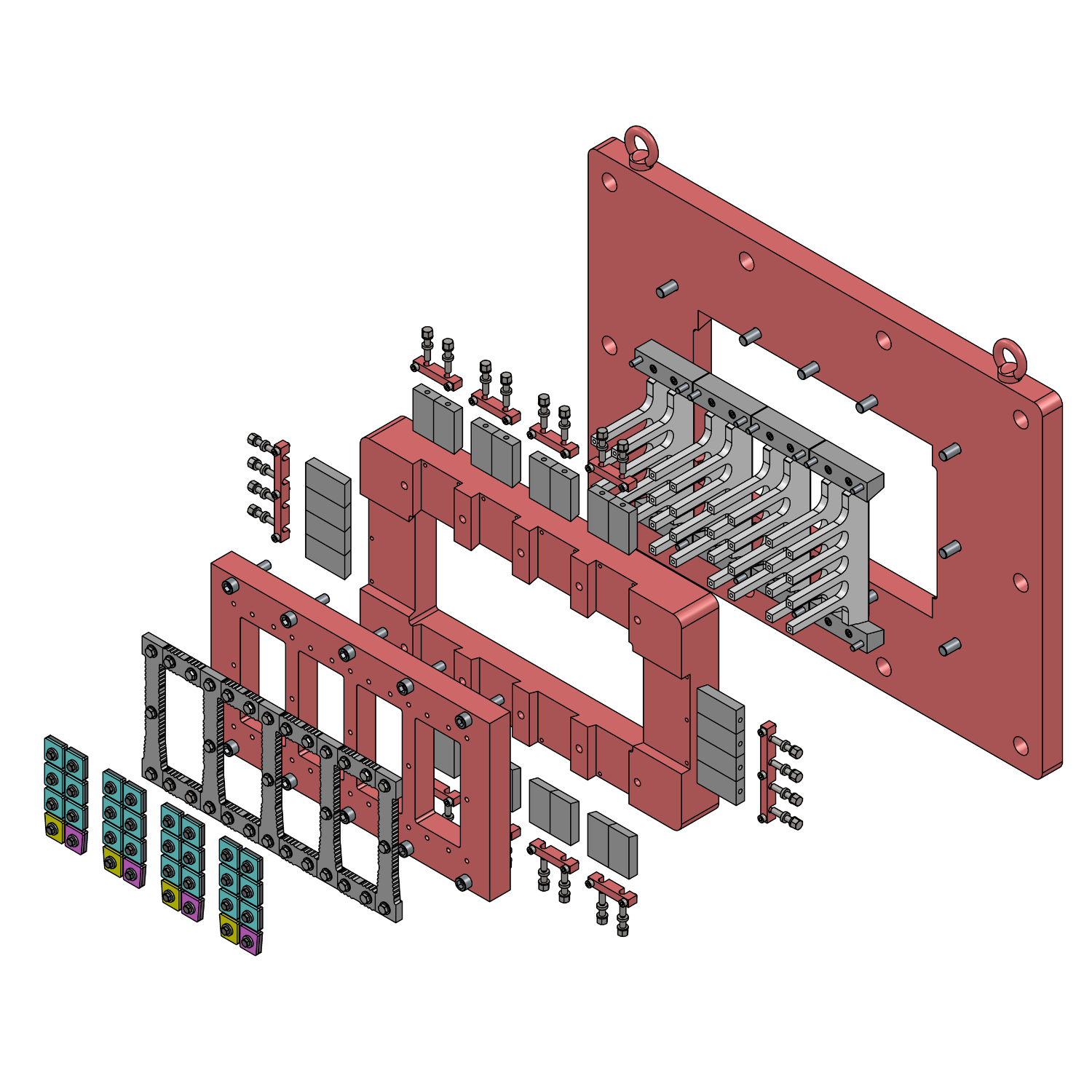

Our extrusion dies for bricks are designed to ensure optimal extrusion and adapt to your production requirements:

Standard dies: Available in 8 or 12 outlets configurations, ideal for regular needs and high production speeds.

Custom dies: Tailored design based on your specific processes, materials, and production goals.

Combs

- MF Pack: ABRA-STEEL® wear-resistant steel

- MF Fus: Complex alloy with high tungsten carbide content: Infiltration on a steel base

- MF Duo: MF Pack insert + wear-resistant section in sintered tungsten carbide

Cores

- MF Pack: ABRA-STEEL® wear-resistant steel

- MF Fus: Complex alloy with high tungsten carbide content: Infiltration on a steel base

- MF FTC: Solid non-recycled sintered tungsten carbide

- MF Duo: MF Pack insert + contour in sintered tungsten carbide

Brackets

- MF Pack: ABRA-STEEL® wear-resistant steel

- MF Perf: MF Pack + Hardening heat treatment

- MF Cr3: MF Pack + Hard chrome plating

- MF Max: MF Pack with BMI FR82® shielding and MF FTC anti-wear bushings on core support rods

Plates and Frames

- MF Pack: ABRA-STEEL® wear-resistant steel

- MF Perf: MF Pack + Hardening heat treatment (depending on finish)

- Description

Our standard dies are optimized and sized according to your installation and needs.

We adapt them to your clay shrinkage and customize the tooth design upon your request.

The design of our dies simplifies your maintenance and enhances the reliability of your production with high-quality materials.

- Characteristics

Independent outlet adjustment with our externally adjustable brake system and stackable counter cores to optimize output speeds.

Multiple finishes available to adapt to your production and optimize the lifespan of the parts.

Improved compression with a long chassis length.

Multi-outlet conical comb carrier frame for better clay distribution.

Independent brackets per outlet and rod system with anti-rotation to ensure better adjustment.

Combs

- MF Pack: ABRA-STEEL® wear-resistant steel

- MF Fus: Complex alloy with high tungsten carbide content: Infiltration on a steel base

- MF Duo: MF Pack insert + wear-resistant section in sintered tungsten carbide

Cores

- MF Pack: ABRA-STEEL® wear-resistant steel

- MF Fus: Complex alloy with high tungsten carbide content: Infiltration on a steel base

- MF FTC: Solid non-recycled sintered tungsten carbide

- MF Duo: MF Pack insert + contour in sintered tungsten carbide

Brackets

- MF Pack: ABRA-STEEL® wear-resistant steel

- MF Perf: MF Pack + Hardening heat treatment

- MF Cr3: MF Pack + Hard chrome plating

- MF Max: MF Pack with BMI FR82® shielding and MF FTC anti-wear bushings on core support rods

Plates and Frames

- MF Pack: ABRA-STEEL® wear-resistant steel

- MF Perf: MF Pack + Hardening heat treatment (depending on finish)

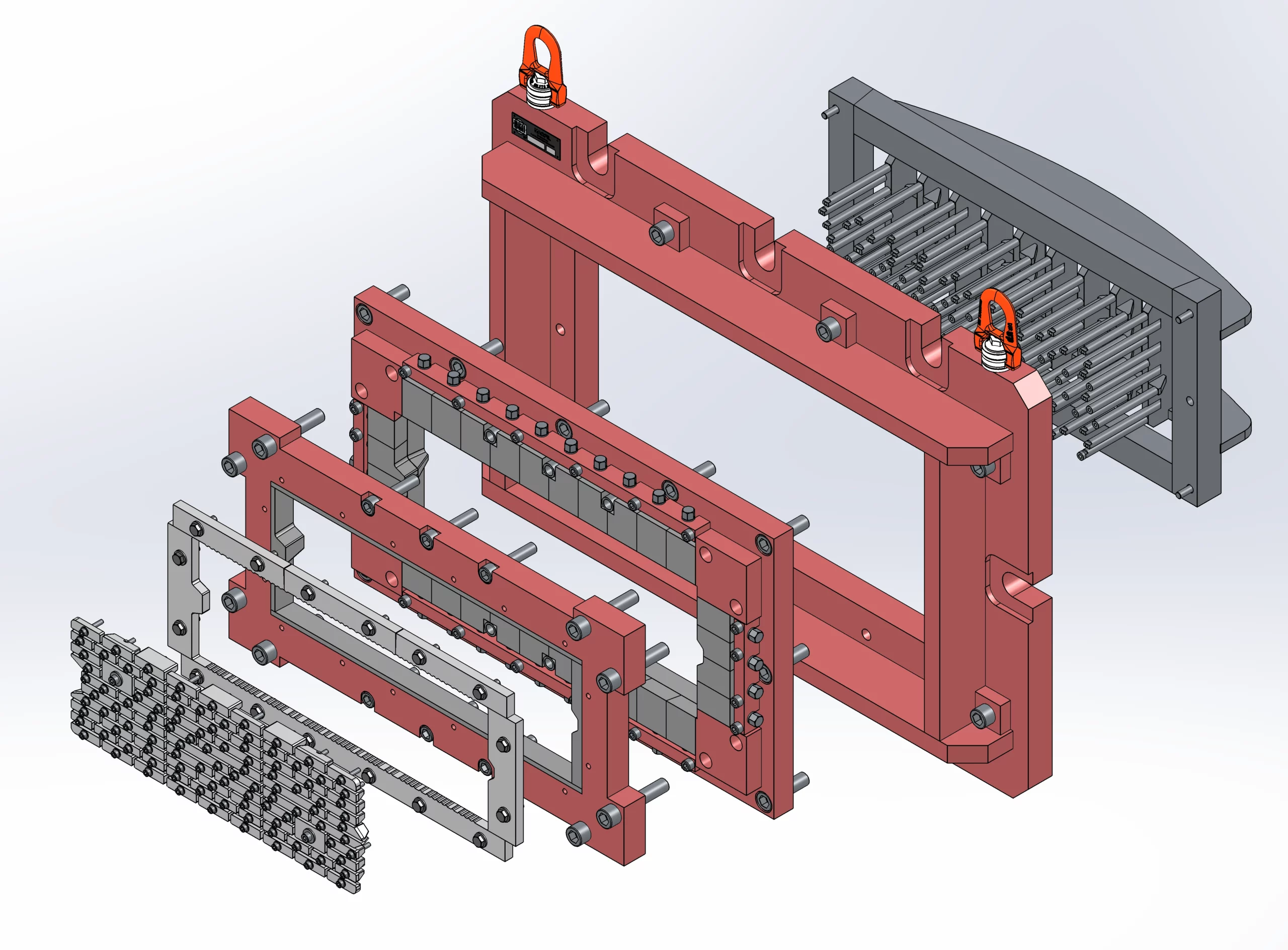

- Description

Our custom dies are developed and designed in collaboration with your technical teams to provide the best solution to your needs.

The design of our dies simplifies your maintenance and enhances the reliability of your production with high-quality materials.

- Characteristics

Outlet adjustment with our externally adjustable brake system to optimize production and improve quality without wasting time on disassembly.

Removable inlet frames to simplify maintenance and extend lifespan.

The design of the brackets is custom-made based on your products to promote clay flow and reduce cracks.

The core design is engineered to balance the outlet with the option to adapt counter-cores.

Adjustable combs to tailor the product to your shrinkage.